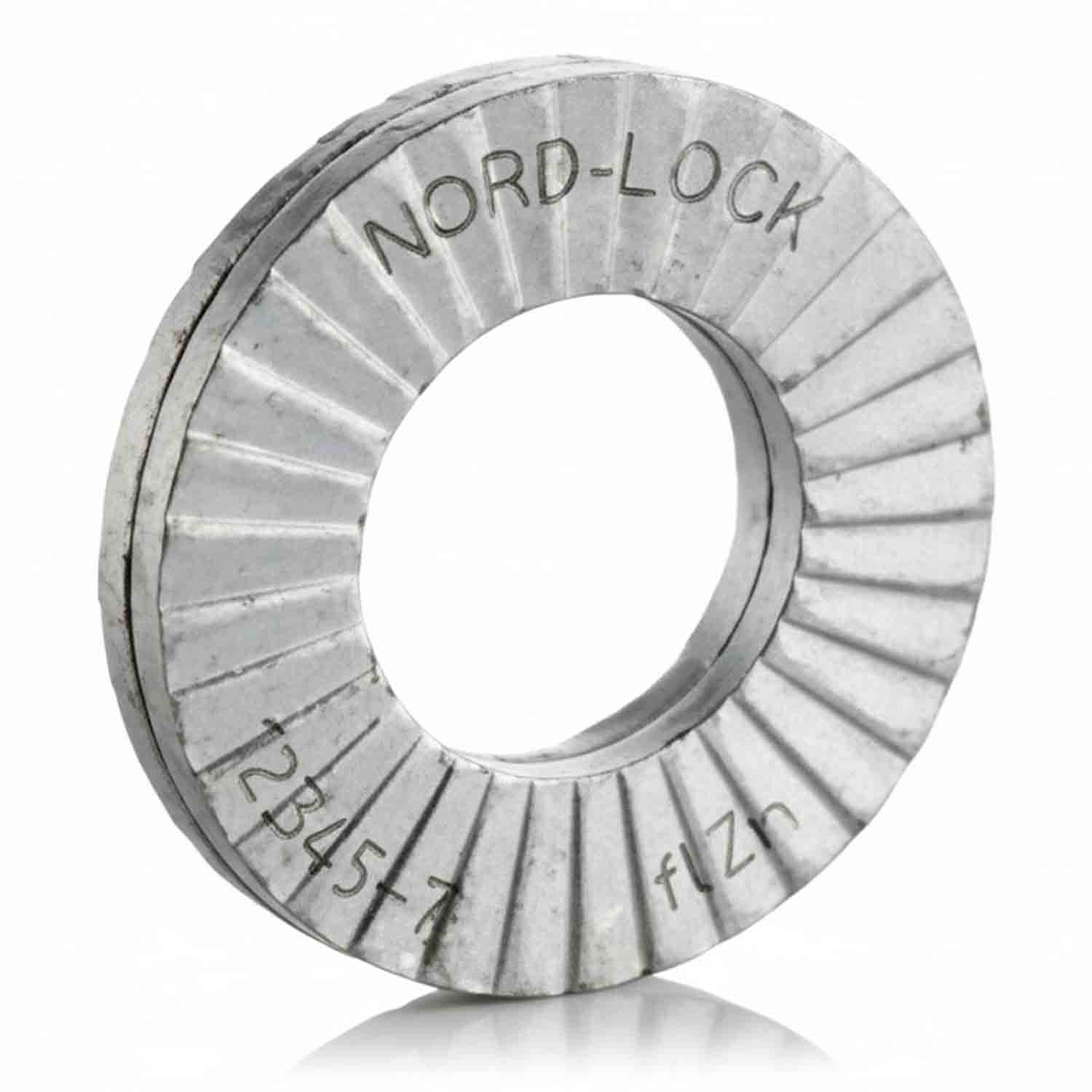

Yellow Enterprises, presents a premium stainless steel closed Nord Lock washer. Designed for critical bolted assemblies subject to heavy vibration and dynamic loads, this washer features dual-cam and radial-tooth geometry to secure preload and prevent loosening. Ideal for petrochemical, power, transport & industrial applications.

A closed Nord Lock washer employs the proven wedge-locking principle: paired washers with cam faces on the inside and radial teeth on the outside work together to lock a bolted joint by tension rather than friction.

The term “closed” refers to the washer configuration supplied as two mating parts pre-assembled or paired specifically for precision locking. In stainless steel form, the closed Nord Lock washer is particularly well suited to corrosive, high-temperature, and high-load environments.

Superior bolt security: The cam-and-tooth geometry ensures the wedge angle is greater than the thread pitch, creating a locking effect that prevents joint rotation or loosening even in high vibration applications.

Stainless steel construction: Made from premium grade stainless alloy, offering excellent corrosion resistance and durability in harsh industrial environments (chemical, marine, offshore).

Re-usability and reduced maintenance: Unlike many locking systems, the closed Nord Lock washer is designed for reuse, reducing operational cost and maintenance downtime.

Wide temperature and environment range: Suitable for extreme temperature fluctuations, high dynamic loads and demanding bolted assemblies in sectors such as power generation, heavy machinery, rail, oil & gas and more.

Precise preload control: Assembly is efficient and consistent—no re-tightening required—helping improve overall joint reliability.

Manufactured by Yellow Enterprises: As a specialist in precision metal fasteners, Yellow Enterprises ensures each washer is manufactured with tight tolerances, full traceability, and rigorous quality assurance.

While exact sizes, dimensions and stainless grades will vary depending on application and customer requirement, key technical aspects of the closed Nord Lock washer include:

The stainless steel closed Nord Lock washer from Yellow Enterprises finds application across a broad range of industrial environments:

Oil & Gas / Petrochemical: Critical bolted joints in refineries, processing plants, supporting structures and heavy equipment where vibration and dynamic stress are present.

Power Generation: Turbine mounts, generator frames, boiler support structures, nuclear and conventional power plants where joint security is paramount.

Transportation / Heavy Machinery: Rail, automotive, construction equipment, mining where repeated vibration and shock demand high-security bolting solutions.

Marine & Offshore: Platforms, ship structures, deck machinery exposed to harsh saline environments – stainless grade ensures corrosion resistance.

Steel / Structural Construction: Where large-diameter bolts and structural frames require locking against loosening over repeated load cycles.

Yellow Enterprises stands out in the fastener manufacturing sector for several reasons:

Established in 2017 in Pune, Maharashtra, India, with a dedicated facility for precision stainless steel manufacturing.

Expertise in stainless steel blind self-clinch nuts and fastener solutions makes the company uniquely positioned to offer complementary bolted joint components alongside the closed Nord Lock washer.

Commitment to quality: Manufacturing to ISO standards, full traceability, strict inspection protocols and customer-specific solutions.

Strong service ethos: Ability to supply domestic and international markets, customization in dimensions, stainless grades and finishes.

One-stop sourcing: For customers looking for both locking washers and other related stainless fasteners, Yellow Enterprises reduces supply-chain complexity.